In the world of travel and baggage, accurately measuring luggage is not a trivial matter, but a critical step that affects many aspects, from ensuring compliance with airline regulations to optimizing packing efficiency. In this article, we'll walk you through the detailed process of measuring a suitcase and discuss the role of plastic sheet extruders and baggage vacuum formers in the manufacture of suitcases, which are critical to the measurement standards and structural integrity of the final product.

Why is measuring luggage so important?

Before delving into the measurement process, it is important to understand its importance. Airlines around the world place strict limits on the size and weight of checked and carry-on luggage. For example, most major airlines allow carry-on baggage with dimensions up to 22 x 14 x 9 inches (56 x 36 x 23 cm) and checked baggage with maximum linear dimensions (length + width + height) of approximately 62 inches (157 cm). Exceeding these limits may result in additional fees or even denial of baggage transportation. Additionally, accurate measurements help travelers plan their packing more efficiently by ensuring that all essentials fit and avoiding overstuffing the suitcase, which could damage it or cause it to become overweight.

Tools for measuring

To accurately measure your suitcase, you'll need some basic tools. A soft tape measure is the most common and essential tool. It allows you to measure curved surfaces and irregular shapes with ease. A straightedge or yardstick can also be used to accurately measure straight edges. In addition, a flat surface, such as a floor or a large table, is needed to ensure that the luggage is measured in a stable and level position.

Step-by-step measurement process

Measuring Length

Place the suitcase on a flat surface with the wheels on the ground and the handle in the retracted position. The length of the suitcase is usually measured from the longest side, excluding any protruding parts such as wheels or handles. Using a tape measure, measure from one end of the suitcase and extend it to the other end, keeping the tape straight and parallel to the longest side of the suitcase. Make sure to keep the measurement straight to get an accurate reading. Measurements are given in inches or centimeters.

Measuring the Width

Next, measure the width of the luggage. Rotate the luggage so that the side to be measured is facing you. The width is the distance from one side of the luggage to the other, perpendicular to the direction of the length. Use the tape measure again to measure the width of the luggage, avoiding any wheels or handles that may extend beyond the case. Make sure the tape measure is horizontal and straight to get an accurate measurement of the width. Make a note of the measurement.

Measuring the height

The height of a suitcase is the distance from the bottom (excluding the wheels) to the top and is usually measured with the handle fully extended. However, on some airlines the height is measured with the handle retracted. Check the specific airline regulations for the flight you will be traveling on. Extend the tape measure from the bottom of the suitcase (where it touches a flat surface) to the highest point of the suitcase, either at the top edge or with the handle fully extended. Take care to measure vertically to get the correct height value and record it.

Calculating Linear Dimensions

After measuring the length, width and height, you may need to calculate the linear dimension, which is the sum of these three dimensions. Airlines often use this value to determine if a suitcase meets their dimensional requirements. For example, if a suitcase has a length of 20 inches, a width of 12 inches and a height of 8 inches, the linear dimension would be 20 inches + 12 inches + 8 inches = 40 inches.

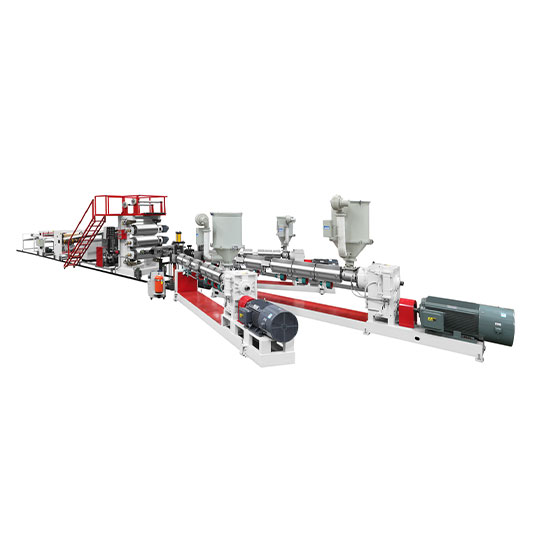

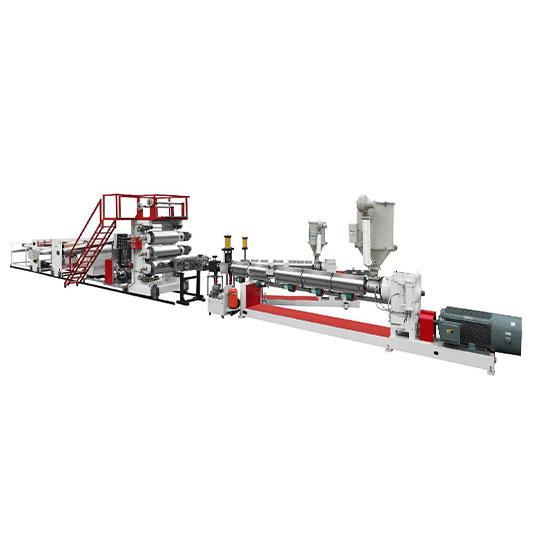

The Role of Plastic Sheet Extruders in Luggage Manufacturing

Plastic sheet extruders play a vital role in the production of luggage materials. The machine takes raw plastic materials such as polyethylene or polypropylene and melts them at high temperatures. The melted plastic is then extruded through a die to form a continuous sheet. During the extrusion process, the thickness and width of the plastic sheet can be precisely controlled. This is critical because the dimensions of the plastic sheet directly affect the final size and shape of the luggage.

For example, if the plastic sheet is too thick, it may cause the luggage to be too heavy, thus affecting the overall weight limit. On the other hand, if the sheet is too thin, the luggage may lack the necessary strength and durability. Measurement accuracy during the extrusion process ensures that the plastic sheet meets the specifications required for luggage manufacturing, which in turn affects the accuracy of the final dimensions of the luggage.

Conclusion

Accurately measuring luggage is an essential skill for travelers, and understanding the manufacturing process for plastic sheet extruders and luggage vacuum formers can help provide insight into how luggage dimensions are achieved. By following a step-by-step measurement process and understanding the importance of measurement in luggage manufacturing, travelers can ensure that their luggage meets the necessary requirements to make their travel experience smoother and easier. Whether you're a frequent or occasional traveler, taking the time to properly measure your luggage is worth it.