Entering the world of CNC plastic cutting machines can seem daunting for beginners, but with the right approach, you can quickly gain confidence in operating these powerful tools. Whether you're involved in plastic fabrication, prototyping, or a DIY project, mastering the operation of CNC plastic cutting machines opens up a world of precision and creativity. Here are some effective steps and tips to help you get up to speed in no time.

Understand the Basics

Before you start any hands - on operation, it's crucial to familiarize yourself with the fundamental components and functions of the CNC plastic cutting machine.

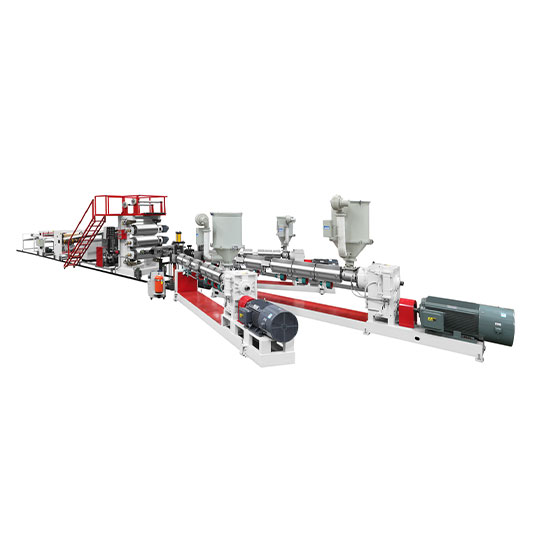

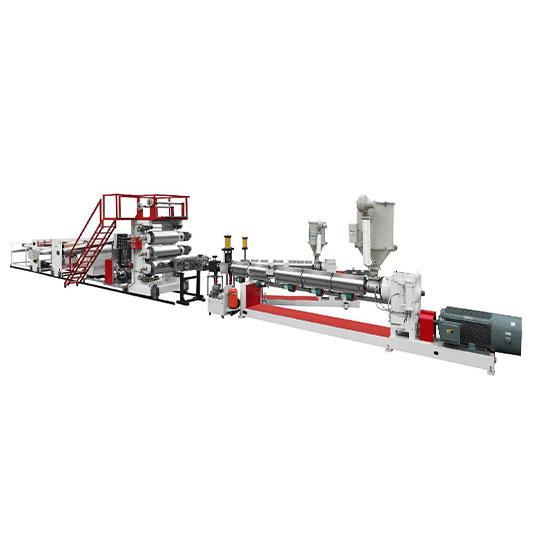

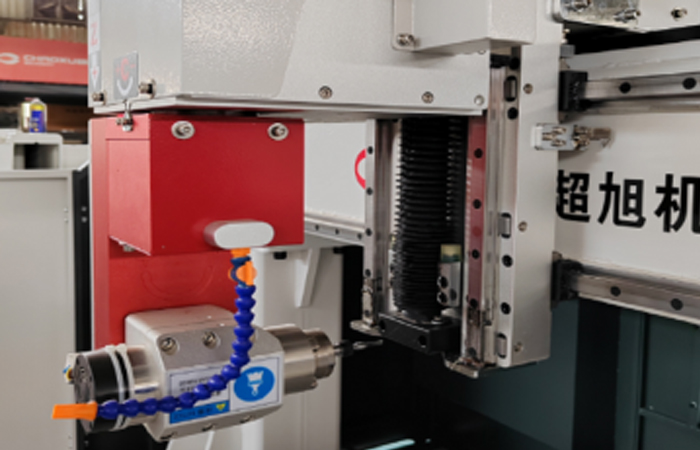

The machine typically consists of a cutting head, a table where the plastic material is placed, a control panel, and a computer - controlled system. The cutting head can vary depending on the type of cutting technology used, such as laser, blade, or waterjet. For example, a laser - based cutting head emits a high - energy laser beam to melt and vaporize the plastic, while a blade - type head physically cuts through the material.

Spend time studying the machine's manual, which will provide detailed information about its features, safety guidelines, and basic operation procedures. Understanding terms like "axis movement," "feed rate," and "cutting depth" will be essential as you progress.

Learn the Software

CNC plastic cutting machines rely on specialized software to translate design files into cutting instructions. The two main types of software involved are CAD (Computer - Aided Design) and CAM (Computer - Aided Manufacturing).

CAD software is used to create or import the design of the object you want to cut. Popular CAD programs like AutoCAD, SolidWorks, or FreeCAD offer a wide range of tools for designing complex shapes and patterns. For beginners, it's advisable to start with simpler designs and gradually work your way up to more intricate ones.

CAM software, on the other hand, takes the CAD design and converts it into a set of instructions that the CNC machine can understand. It determines the cutting path, tool selection, and other parameters. Software like Fusion 360 combines both CAD and CAM functions, making it a convenient choice for beginners. Many of these software programs have online tutorials, video courses, and user forums where you can learn from others and ask questions.

Safety First

Safety should always be your top priority when operating a CNC plastic cutting machine. Before you start any operation, make sure to wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask.

Understand and follow all safety protocols outlined in the machine's manual. For example, never reach into the cutting area while the machine is running, and always ensure that the plastic material is securely fastened to the table to prevent it from moving during cutting. Familiarize yourself with the emergency stop button and know how to use it in case of an unexpected situation.

Practice on Simple Projects

Once you have a basic understanding of the machine and the software, it's time to start practicing on simple projects. Begin with small, flat plastic pieces and basic shapes like squares, circles, and triangles. This will help you get a feel for how the machine moves, how to set the cutting parameters, and how to control the quality of the cut.

Adjust parameters such as the cutting speed, feed rate, and cutting depth to see how they affect the outcome. For instance, increasing the cutting speed might save time but could result in a less precise cut, while decreasing it might give a cleaner cut but take longer. Keep a record of the settings you use and the results you achieve, so you can refer back to them in the future.

Troubleshoot Common Issues

As you gain more experience, you're likely to encounter some common issues. These could include problems like uneven cuts, burnt edges (in the case of laser cutting), or the machine not following the design path correctly.

Most CNC plastic cutting machine manufacturers provide troubleshooting guides in their manuals or on their websites. Additionally, online communities and forums dedicated to CNC machining are great resources for getting advice from experienced users. By learning how to identify and solve these common problems, you'll become more self - sufficient in operating the machine.

Seek Further Training and Resources

If possible, consider enrolling in a formal training course on CNC plastic cutting machine operation. Many technical schools, community colleges, and vocational training centers offer such courses, which can provide hands - on instruction from experienced instructors.

In conclusion, mastering the operation of CNC plastic cutting machines is an achievable goal for beginners. By understanding the basics, learning the software, prioritizing safety, practicing regularly, troubleshooting issues, and seeking additional training, you'll be well on your way to creating high - quality plastic cuts with confidence. With time and experience, you'll be able to take on more complex projects and unlock the full potential of these amazing machines.