In the bustling world of travel and luggage manufacturing, the ability to accurately measure a suitcase is a skill that holds significant practical value for both travelers and industry professionals. A precise measurement not only ensures that your luggage complies with airline regulations but also offers insights into the intricate manufacturing processes involving key equipment like the Plastic Sheet Extruder Machine and the Luggage Vacuum Forming Machine. This article will take you through a detailed exploration of suitcase measurement, while highlighting the roles these machines play in shaping the final product.

The Significance of Accurate Suitcase Measurement

For travelers, accurate suitcase measurement is the first step in a hassle - free journey. Airlines around the globe enforce strict size and weight limits for both carry - on and checked luggage. These regulations are in place to ensure the safety and efficiency of aircraft operations. For example, in the United States, major airlines such as American Airlines and Delta Air Lines have specific size requirements for carry - on bags, typically allowing dimensions not exceeding 22 x 14 x 9 inches. Deviating from these measurements can lead to additional fees, or worse, your luggage being denied boarding.

From a manufacturing perspective, precise measurement is the cornerstone of producing high - quality suitcases. It directly influences the functionality, durability, and aesthetic appeal of the product. A suitcase that is inaccurately measured may not only fail to meet customer expectations but also face difficulties in the market, potentially damaging the brand's reputation.

Essential Tools for Measuring a Suitcase

To achieve accurate measurements, you'll need a set of reliable tools. A flexible measuring tape is an absolute must - have. Its flexibility allows it to contour around the various shapes and curves of a suitcase, ensuring that you can measure every dimension precisely. A rigid ruler or yardstick can also be useful, especially for measuring straight edges with high precision. Additionally, having a flat, stable surface, such as a large table or a clean floor, is crucial. This provides a consistent and level base for measuring, minimizing any potential errors caused by uneven surfaces.

Step - by - Step Guide to Measuring a Suitcase

Measuring the Length

Place the suitcase on the flat surface with the wheels resting on the ground and the handle fully retracted. The length of the suitcase is measured along its longest side, excluding any protruding elements like wheels, handles, or external pockets. Extend the measuring tape from one end of the suitcase to the other, keeping it straight and parallel to the longest edge. Make sure the tape is taut but not overly stretched, as this could lead to inaccurate readings. Record the measurement in either inches or centimeters.

Measuring the Width

Rotate the suitcase so that the side you want to measure for width is facing you. Similar to the length measurement, avoid including any parts that extend beyond the main body of the suitcase, such as wheels or side pockets. Use the measuring tape to measure from one side of the suitcase to the other, perpendicular to the length. Ensure the tape is level and straight throughout the measurement process. Jot down the width measurement once you're confident it's accurate.

Measuring the Height

The height measurement can vary depending on the specific requirements. In most cases, when measuring for airline regulations, the height is measured from the bottom of the suitcase (excluding the wheels) to the top when the handle is in its fully extended position. However, some airlines may have different rules, so it's always important to double - check. Again, use the measuring tape to measure vertically, starting from the base and ending at the highest point of the extended handle or the top of the suitcase. Note down the height value accurately.

Calculating the Linear Dimension

Once you have the length, width, and height measurements, you may need to calculate the linear dimension. This is simply the sum of the three measurements and is commonly used by airlines to determine if a suitcase meets their overall size requirements. For example, if a suitcase has a length of 20 inches, a width of 10 inches, and a height of 12 inches, the linear dimension would be 20 + 10 + 12 = 42 inches.

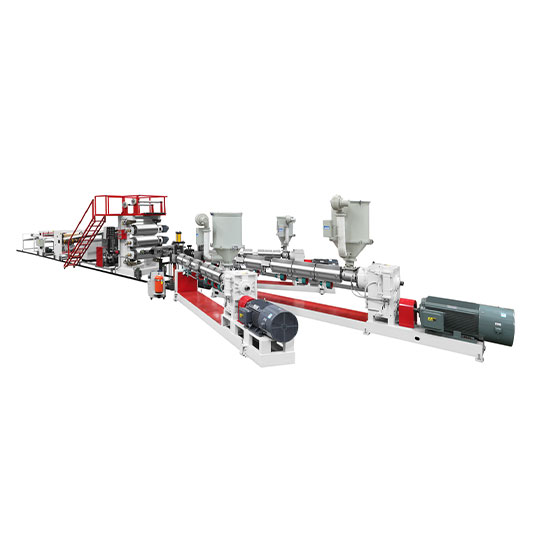

The Role of the Plastic Sheet Extruder Machine in Suitcase Manufacturing

The Plastic Sheet Extruder Machine is a key player in the production of suitcase materials. This machine takes raw plastic materials, which can range from polyethylene to polypropylene, and transforms them into plastic sheets. The process begins with feeding the raw plastic into the extruder, where it is melted at high temperatures. Once melted, the plastic is forced through a die, which shapes it into a continuous sheet.

The dimensions of the plastic sheet produced by the extruder machine are carefully controlled. The thickness of the sheet is a critical factor, as it affects the strength and weight of the final suitcase. A thicker sheet may provide more durability but could also increase the weight of the suitcase, potentially making it less convenient for travelers. On the other hand, a thinner sheet may be lighter but might compromise on strength. The width of the sheet also needs to be precise, as it determines the maximum size of the suitcase components that can be formed later. This precise control over the dimensions of the plastic sheet is essential for ensuring that the final suitcase meets the required size and quality standards.

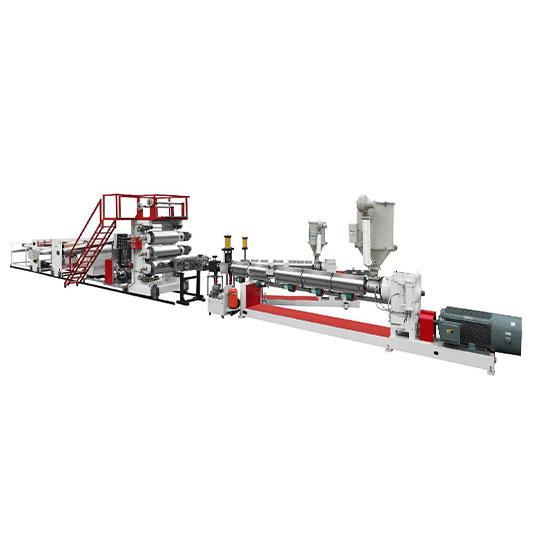

The Function of the Luggage Vacuum Forming Machine

After the plastic sheets are produced, the Luggage Vacuum Forming Machine comes into action. This machine uses the principle of vacuum forming to shape the plastic sheets into the desired suitcase form. The process starts with heating the plastic sheet until it becomes soft and pliable. Once heated, the sheet is placed over a mold that is shaped like the suitcase. A vacuum is then applied, which sucks the plastic sheet tightly against the mold, conforming it to the exact shape of the suitcase.

The accuracy of the mold used in the vacuum forming process is of utmost importance. Any discrepancies in the mold's dimensions will be reflected in the final product. For example, if the mold is slightly larger or smaller than the intended design, the resulting suitcase will not meet the required size specifications. The vacuum forming process also ensures that the plastic adheres evenly to the mold, creating a smooth and consistent surface. This not only enhances the aesthetic appeal of the suitcase but also contributes to its structural integrity.

Conclusion

Measuring a suitcase accurately is a multi - faceted process that combines practical skills with an understanding of the underlying manufacturing technologies. For travelers, it's a necessary step to avoid travel complications, while for manufacturers, it's a key aspect of producing high - quality luggage. The Plastic Sheet Extruder Machine and the Luggage Vacuum Forming Machine play integral roles in ensuring that the final product meets the required size and quality standards. By mastering the art of suitcase measurement and understanding the manufacturing processes involved, both travelers and industry professionals can make more informed decisions, leading to a better travel experience and improved product quality.