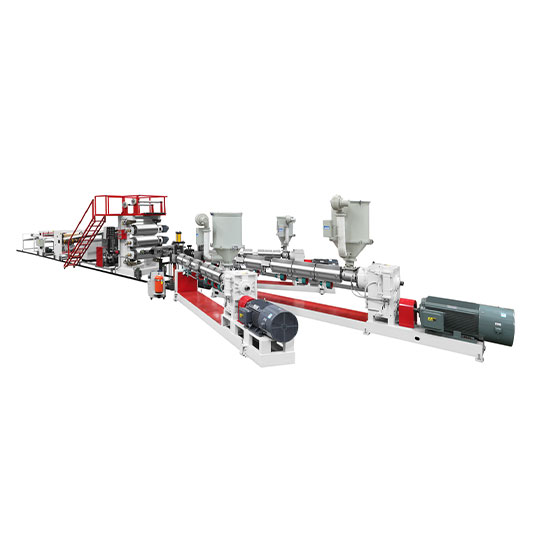

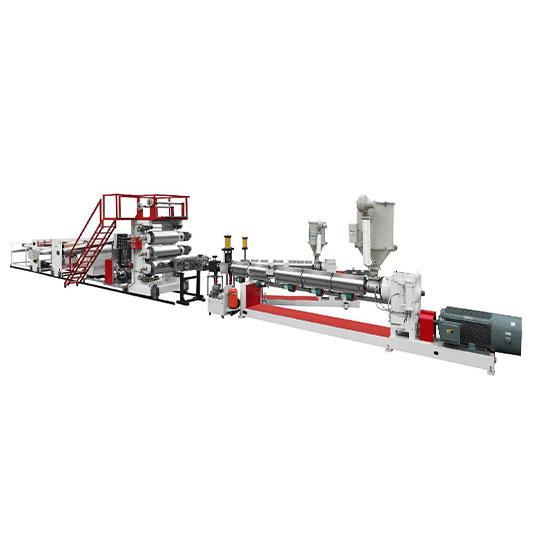

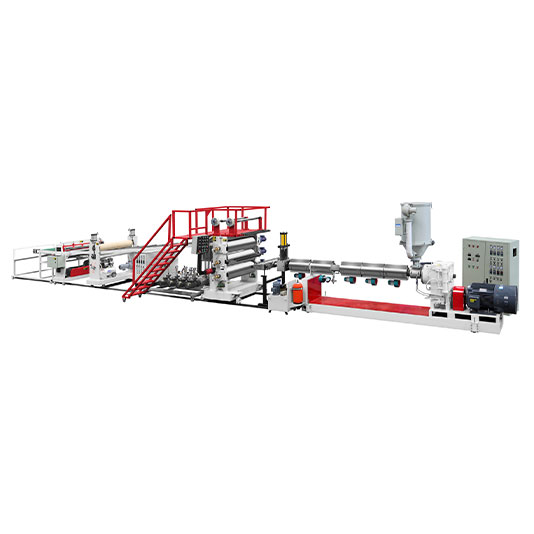

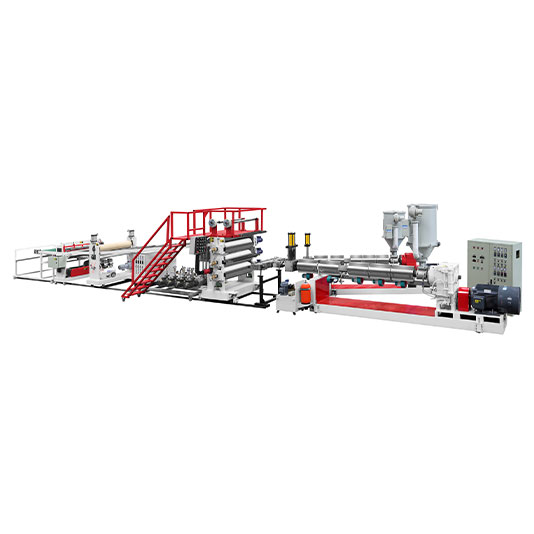

Plastic Sheet Extruder Machine

As a plastic sheet extruder machine manufacturer, Chaoxu provides you with complete high-end luggage production equipment solutions. Meet your production needs, suitable for processing ABS, PC, PS, HDPE and other materials. The equipment uses advanced technology to precisely control temperature, pressure and time to ensure consistent quality and appearance of each product.