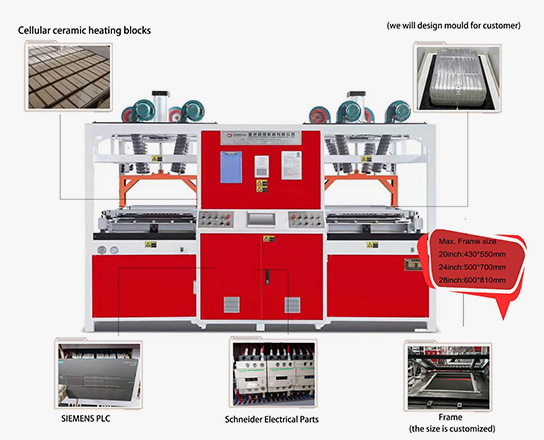

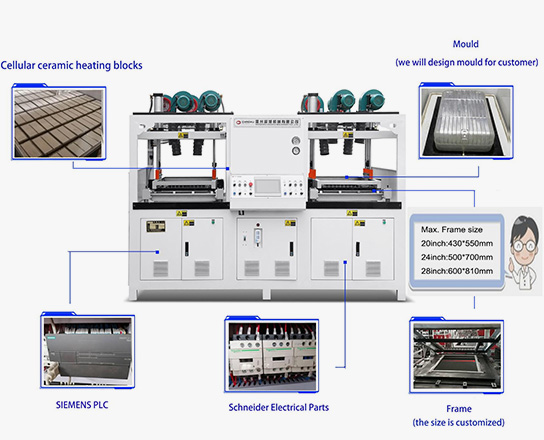

Luggage Vacuum Forming Machine

Chaoxu’s Luggage Vacuum Forming Machine adopts PLC control, hydraulic drive, and is equipped with upper and lower heating elements, which enhances the durability and impact resistance of the luggage. Suitable for sheet forming of ABS, PC or recycled materials.