How is a Suitcase Made?

A modern suitcase is a sophisticated blend of design, materials, and precision engineering. Its journey from raw plastic to your trusted travel companion involves a coordinated series of steps on an automated luggage production line. This ensures efficiency, consistency, and high quality. Here’s a step-by-step look at the process, highlighting the crucial machinery involved.

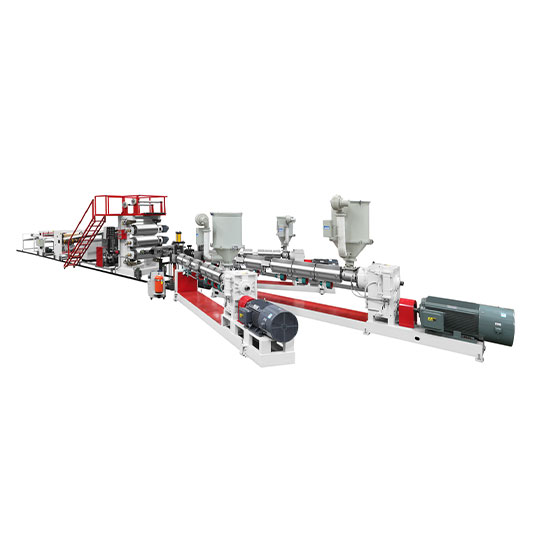

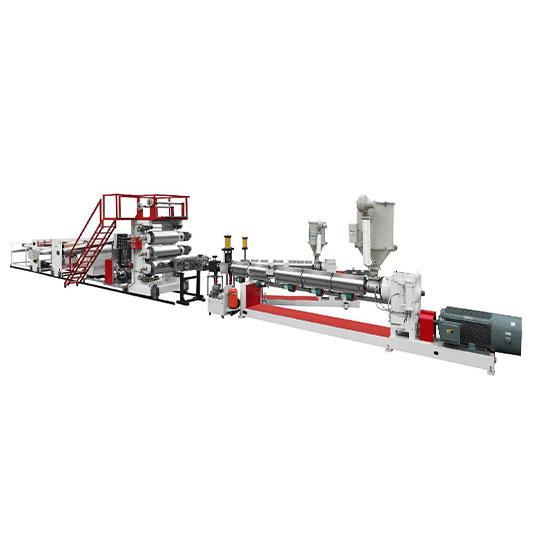

1. Creating the Raw Material: Plastic Sheet Extrusion

The process begins with the Plastic Sheet Extruder Machine. This machine melts down raw plastic compounds (like polycarbonate or ABS) and forms them into continuous, uniform sheets of specific thickness. These sheets are then cooled and cut into large panels, ready to be shaped. The quality and properties of these sheets are fundamental to the suitcase's final strength and weight.

2. Shaping the Shell: Vacuum Forming

The flat plastic panels are then transferred to a Luggage Vacuum Forming Machine. Here, a panel is heated until pliable and then draped over a detailed mold of the suitcase shell. A powerful vacuum pulls the air out, forcing the soft plastic to conform perfectly to the mold's contours. This creates the distinctive top and bottom halves of a hard-shell suitcase with precise dimensions and design details.

3. Precision Cutting and Trimming

After forming, the shells move to the trimming station. A CNC Plastic Cutting Machine is the star here. Following digital blueprints, its computer-controlled cutting tools trim off excess material (a process called "de-flashing") and cut out precise openings for components like handles and locks. This step is critical for ensuring that all parts fit together seamlessly later on the **luggage production line**.

For other specific cuts or tasks, a general Plastic Cutting Machine might be used to handle secondary trimming or to prepare smaller internal parts.

4. Creating Functional Openings

Before assembly, specific holes for wheels, telescopic handles, and side handles must be punched. A specialized **Plastic Hole Punch Machine** performs this task with speed and accuracy. It cleanly punches through the molded shell, creating uniform openings that are ready to receive their corresponding hardware components.

5. The Heart of Efficiency: The Integrated Luggage Production Line

All these machines are strategically linked to form a smooth, continuous **luggage production line**. This automated line coordinates the flow of components—from the molded shells and internal frames to fabric linings, zippers, wheels, and locks. At assembly stations, workers or robotic arms install these parts. The shells are joined, often using robust rivets or specialized adhesives. The line ensures every suitcase is assembled in a standardized, efficient sequence, from the installation of the telescopic handle to the final attachment of the wheels.

6. Quality Control and Finishing

The final stage of the luggage production line is dedicated to inspection and finishing. Each suitcase undergoes rigorous checks for weight, wheel alignment, zipper function, and handle operation. It is then cleaned, have any protective films removed, and prepared for packaging.

Conclusion

The creation of a suitcase is a testament to modern manufacturing. By integrating specialized machines—like the Plastic Sheet Extruder, Luggage Vacuum Forming Machine, CNC Plastic Cutting Machine, and Plastic Hole Punch Machine — into a cohesive and automated luggage production line, manufacturers achieve the perfect balance of durability, lightweight design, and aesthetic appeal. So, on your next trip, you can appreciate the intricate, technology-driven journey behind every suitcase rolling alongside you.