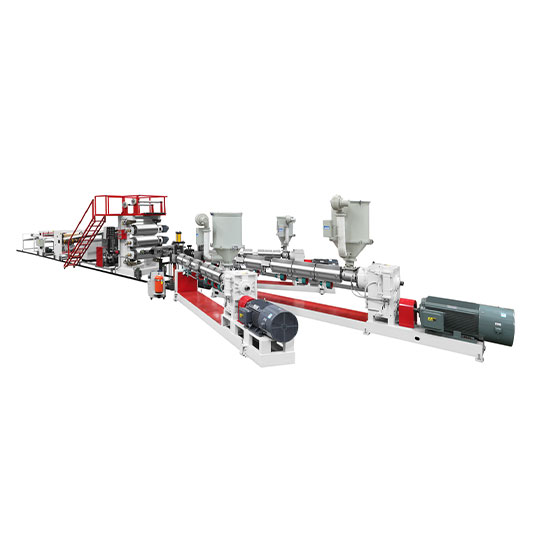

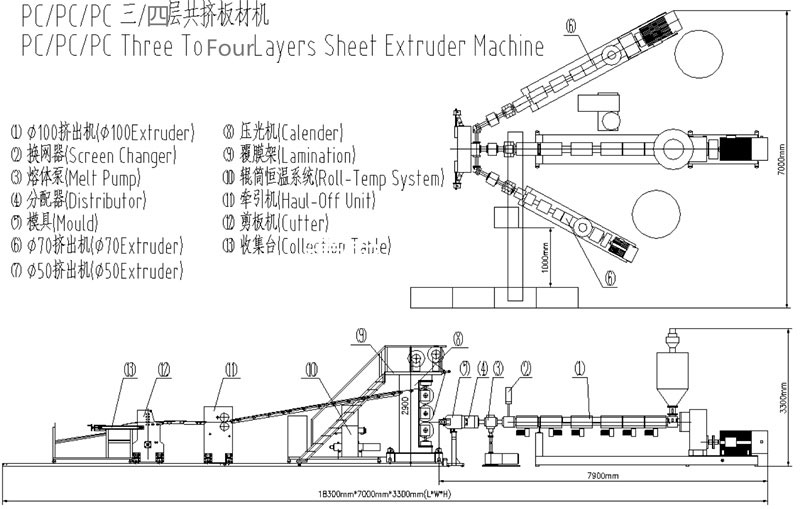

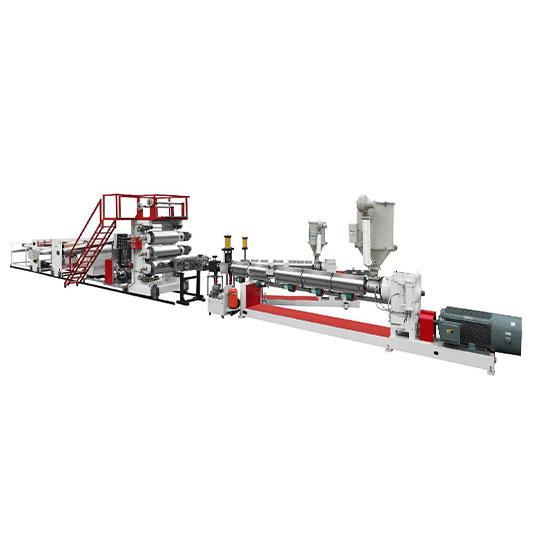

Suitcase Sheet Extrusion Machine

The YX-22P Multilayer Plastic Sheet Extruder Machine is combining an extruder, mold, three-roll calender, temperature controller, hauling unit, cutting device, and electric control cabinet.