In manufacturing, the plastic sheet extruder machine stands as a crucial piece of equipment for transforming raw plastic materials into versatile plastic sheets used in countless applications, from packaging to construction. For beginners stepping into this field, the prospect of operating such a complex machine can seem daunting. However, with the right knowledge, a systematic approach, and some practical tips, quickly mastering the operation of a plastic sheet extruder machine is entirely achievable. This article will guide beginners through the essential steps, key considerations, and best practices to become proficient in operating this vital machinery.

Understanding the Basics of Plastic Sheet Extruder Machine

Components and Their Functions

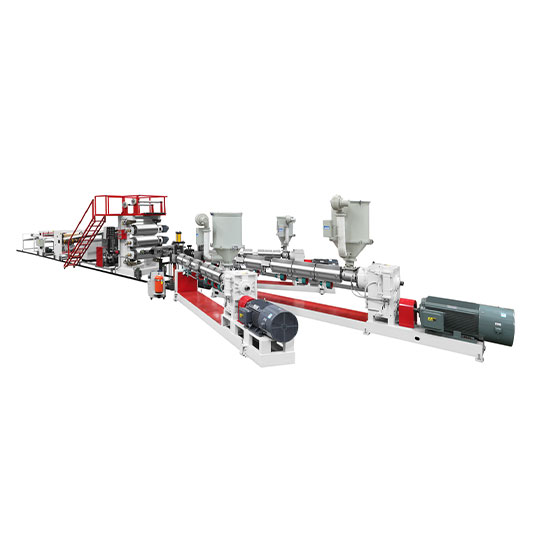

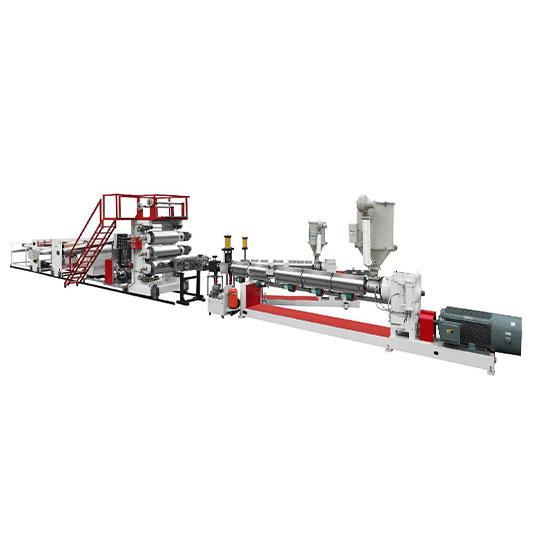

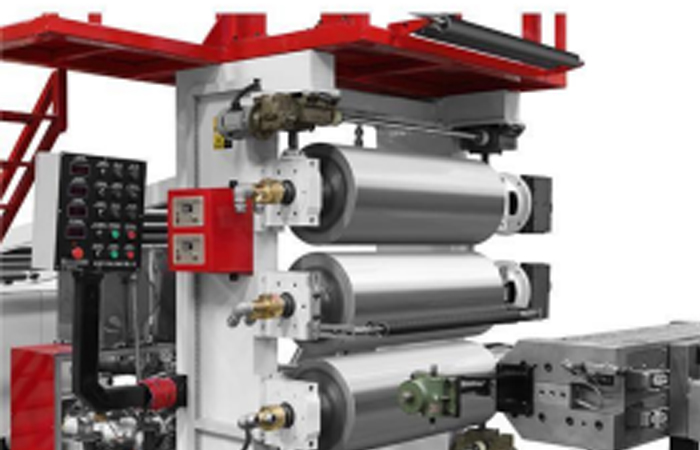

Before diving into the operation, it's essential to familiarize oneself with the main components of a plastic sheet extruder machine. The hopper is where the raw plastic materials, such as pellets of polyethylene or polypropylene, are loaded. These materials then enter the barrel, which is heated to melt the plastic. Inside the barrel, a screw rotates, pushing the molten plastic forward towards the die. The die is a critical component that determines the shape and dimensions of the final plastic sheet, shaping the molten plastic as it exits the extruder. Additionally, there are temperature control systems, gearboxes, and motors that work in tandem to ensure smooth operation. Understanding how each component functions provides a foundation for safe and effective operation.

Working Principle

The working principle of a plastic sheet extruder machine revolves around melting and shaping plastic materials. As the raw plastic enters the heated barrel, the heat causes it to melt. The rotating screw not only conveys the molten plastic but also applies pressure, ensuring a consistent flow. Once the molten plastic reaches the die, it is forced through the die's opening, taking on the desired shape of the sheet. After exiting the die, the plastic sheet is cooled, either by air or water, to solidify it. Gaining a clear understanding of this process helps beginners anticipate what should happen at each stage of operation and recognize when something might be going wrong.

Pre - operation Preparation

Equipment Inspection

Before starting the machine, a thorough inspection is necessary. Check the hopper for any foreign objects or blockages that could disrupt the feeding of raw materials. Examine the barrel and die for signs of wear, cracks, or residue from previous operations. Ensure that all bolts and connections are tightened securely to prevent leaks or vibrations during operation. Additionally, inspect the temperature control sensors and other electrical components to confirm they are functioning properly. A pre - operation inspection helps avoid potential malfunctions and ensures the safety of the operator.

Material Selection and Preparation

Selecting the right raw plastic materials is crucial for achieving the desired quality of the plastic sheet. Different types of plastics have varying melting points, viscosities, and physical properties. Beginners should learn to identify the appropriate plastic for their intended application and ensure that the materials are clean, dry, and free from contaminants. If the materials need to be pre - dried to remove moisture, follow the recommended procedures. Proper material preparation not only affects the quality of the final product but also the performance and lifespan of the extruder machine.

Setting Up the Machine

Adjust the temperature settings of the barrel and die according to the requirements of the plastic material being used. Each type of plastic has an optimal temperature range for melting and extrusion. Set the screw speed, which controls the rate at which the plastic is conveyed through the barrel. Start with lower speeds as a beginner and gradually increase as you gain more experience. Also, configure any additional settings, such as the cooling system parameters, to ensure the plastic sheet solidifies properly after extrusion.

Step - by - Step Operation Process

Starting the Machine

Once the pre - operation preparations are complete, it's time to start the machine. Begin by turning on the power supply and allowing the machine to warm up. Monitor the temperature readings to ensure that the barrel and die reach the set temperatures. Once the temperatures are stable, start the screw rotation at a low speed. Gradually feed the raw plastic materials into the hopper, ensuring a steady and consistent flow. As the plastic starts to melt and move through the barrel, keep an eye on the pressure gauges and other indicators to ensure normal operation.

Monitoring and Adjusting During Operation

During the extrusion process, continuous monitoring is essential. Observe the appearance of the plastic sheet as it exits the die. Check for any irregularities in thickness, width, or surface quality. If the sheet is too thick or thin, adjust the screw speed or the die gap. If there are surface defects, such as bubbles or streaks, it could indicate issues with the temperature, material quality, or screw speed. Make small, incremental adjustments and observe the effects on the sheet quality. Also, regularly check the temperature, pressure, and motor load to ensure they remain within the normal range.

Stopping the Machine

When the production is complete or when there is a need to stop the machine, follow the proper shutdown procedures. First, stop feeding raw materials into the hopper. Then, gradually reduce the screw speed and lower the temperature settings. Allow the remaining plastic in the barrel to be extruded completely. Once the barrel is mostly empty, turn off the screw rotation and the power supply. Clean the machine thoroughly, removing any remaining plastic residues from the hopper, barrel, and die. This helps prevent material degradation and corrosion, ensuring the machine is ready for the next operation.

Maintenance and Troubleshooting

Regular Maintenance

To keep the plastic sheet extruder machine in optimal condition, regular maintenance is crucial. Clean the machine after each operation to prevent the buildup of plastic residues, which can affect the quality of the next production run. Lubricate the moving parts, such as the screw, gearbox, and bearings, according to the manufacturer's recommendations. Inspect and replace any worn - out components promptly. Regular maintenance not only extends the lifespan of the machine but also ensures consistent and high - quality production.

Troubleshooting Common Issues

Beginners are likely to encounter some common issues during operation. For example, if the plastic sheet has inconsistent thickness, it could be due to uneven temperature distribution, incorrect screw speed, or a misaligned die. If the machine experiences high pressure or motor overload, it might indicate a blockage in the barrel or die, or improper material feeding. Refer to the machine's manual for troubleshooting guides and solutions. If the problem persists, don't hesitate to seek advice from experienced operators or technical support personnel.

In conclusion, while operating a plastic sheet extruder machine may seem challenging at first, beginners can quickly master it by understanding the basics, following proper procedures, and practicing regularly. With a combination of theoretical knowledge and hands - on experience, beginners can become proficient in operating this essential machinery, contributing to efficient and high - quality plastic sheet production.