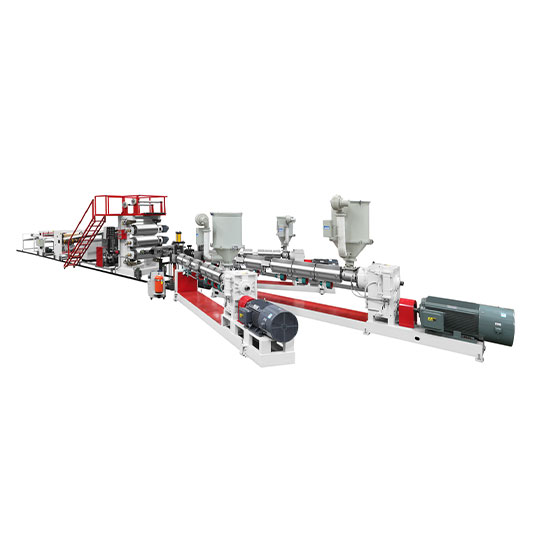

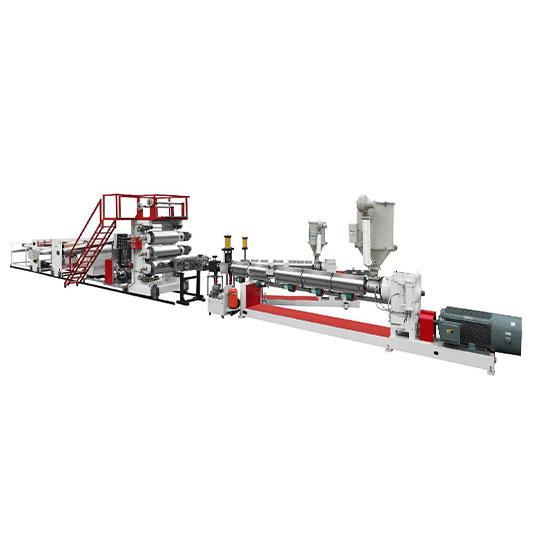

Plastic manufacturers often face a common problem: inconsistent plastic granule sizes. Whether sourcing from different suppliers or using recycled materials, uneven granules can cause feeding blockages, reduce extrusion efficiency, and even affect the quality of the final plastic sheet—especially for small and medium factories that switch between raw material batches frequently. The good news is that a well-designed Plastic Sheet Extruder Machine can solve this issue—here’s how it works, based on practical features and industry experience.

Core Features of the Plastic Sheet Extruder Machine for Granule Adaptation

Adjustable Feeding System

The machine has an adjustable feeding port and screw speed, which can handle granules from small 1mm pellets to larger 5mm granules. For large granules, widen the port and slow the screw to prevent blockages; for small or powdery granules, narrow the port and adjust screw torque to avoid clumping—ensuring smooth feeding without frequent manual intervention.

Compatibility with Multiple Plastic Types

It handles diverse plastics (e.g., dense PC granules for luggage, light ABS granules, and even mixed recycled plastic blends). Its variable-pitch screw design not only melts different-sized granules evenly but also reduces wear on internal parts, extending the machine’s service life no matter the material’s density.

Easy Parameter Adjustments for On-Site Flexibility

The user-friendly control panel features clear digital displays and one-click preset buttons, letting operators tweak feeding speed, screw rotation, and port width quickly. No advanced skills are needed—adjustments take minutes if granule size changes unexpectedly, minimizing production downtime.

About us

If you’re interested in a high-quality Plastic Sheet Extruder Machine, you can check our product page to dive deeper into how it fits your production needs. As a professional manufacturer rooted in the industry, our strengths and expertise lie in:

30 years of focus on intelligent luggage machinery, with in-depth insights into plastic processing pain points—including the nuances of plastic granule adaptation for luggage sheet production.

Pre-sales support: We provide customized initial settings based on your specific granule types (even recycled or blended materials) and production scale, so the machine works smoothly from day one.

After-sales guarantee: 24/7 remote technical support and global on-site assistance (within 48 hours) ensure any granule adaptation issues are resolved promptly, keeping your production on track.

Conclusion

Adapting to different plastic granule sizes doesn’t have to be a production headache. The Plastic Sheet Extruder Machine addresses this challenge through its adjustable feeding system, multi-material compatibility, and easy parameter adjustments—all designed to keep operations stable and efficient.