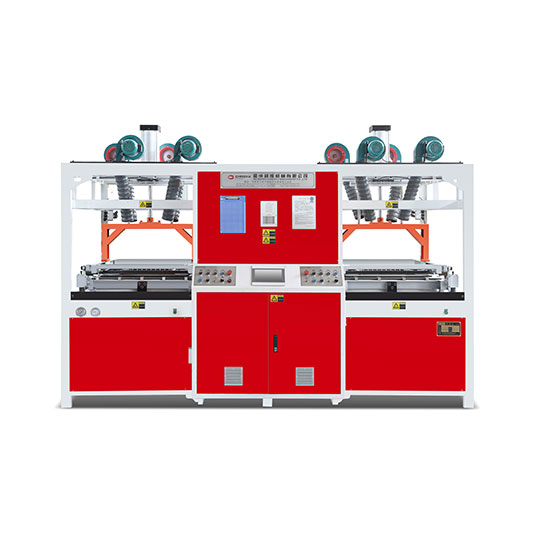

Dual Station Luggage Forming Machine

YX-A Dual Station Luggage Forming Machine adopts automatic operation and upper and lower double heating, equipped with PLC intelligent control system. The machine can be customized according to customer requirements.