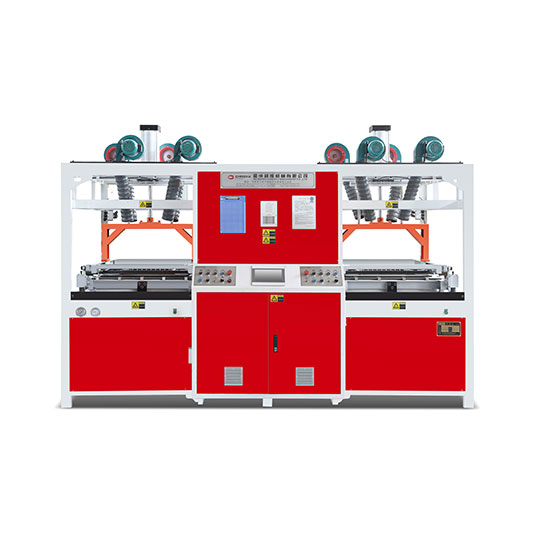

Luggage Case Thermoforming Machine

Designed for high-volume production, this luggage case thermoforming machine uses state-of-the-art thermoforming technology to ensure precise forming of a wide range of materials, including ABS and PC.