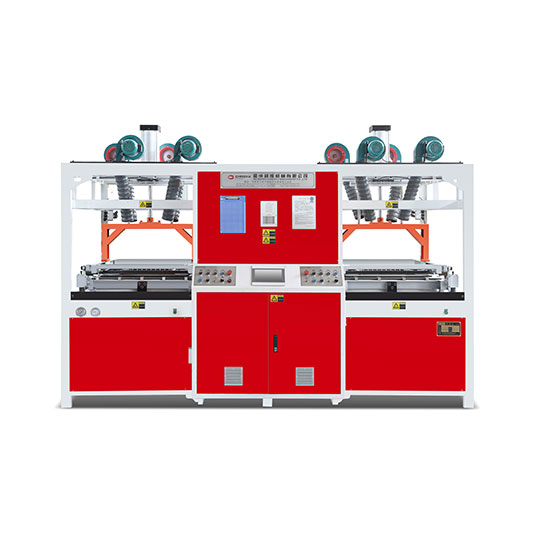

ABS Luggage Vacuum Making Machine

CX-P ABS Luggage Vacuum Making Machine combines dual-station vacuum forming technology and is an advanced equipment designed for the production of luggage made of ABS and other materials. The machine effectively improves production efficiency and manufacturing accuracy through dual-station design.