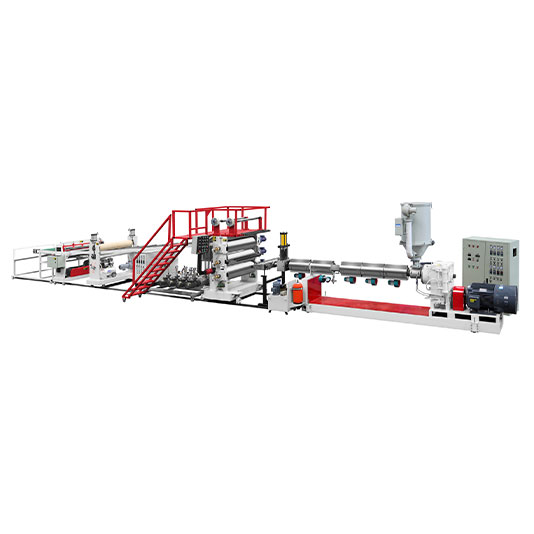

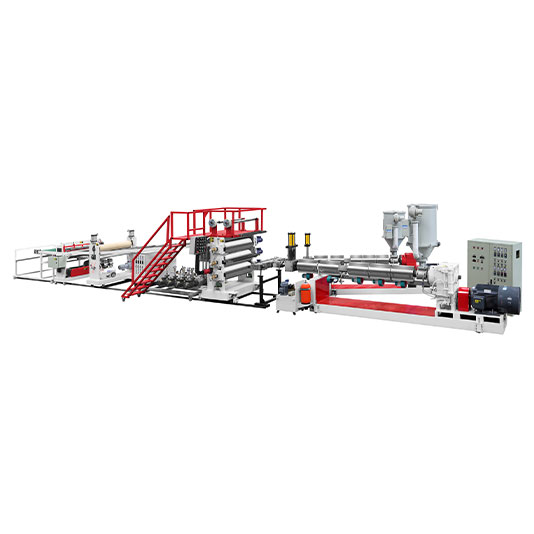

Automatic Luggage Making Machine

YX-21P Automatic Luggage Making Machine: Three-roller calender on extruder machine adoptsvertical structure and the independent control of oil and water control device, to ensure precise constant temperature control.