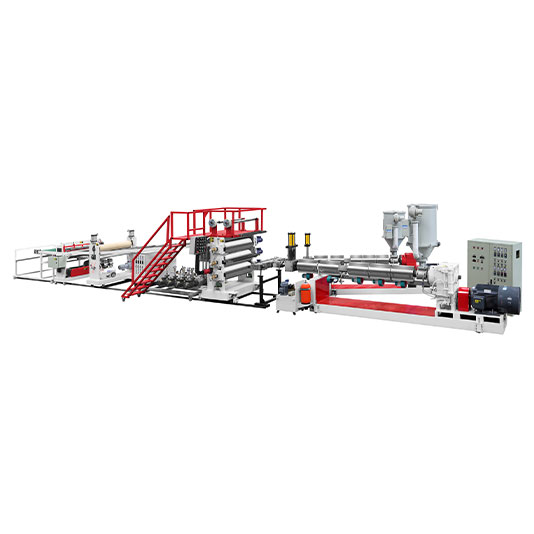

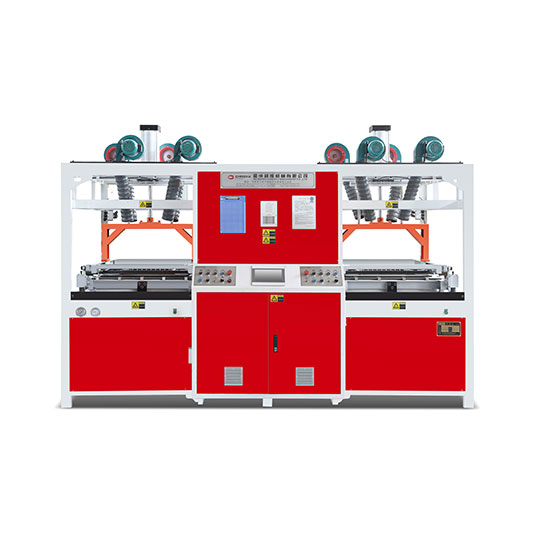

Luggage Bag Making Machine

YX-22AS Luggage Bag Making Machine adopts a hanger design, hard chrome plating and mirror polishing to ensure the production of stable, uniform and smooth plastic sheets.