Plastic sheets are the basic raw material for thousands of everyday and industrial products. The machine that creates these sheets—critical for consistent quality and production efficiency—is the Plastic Sheet Extruder Machine. Many people wonder which industries actually use this equipment to make their products. This article breaks down those key industries and explains how the machine supports their production needs.

Luggage and Bag Manufacturing

Luggage, suitcases, and hard-shell bags all depend on rigid, durable plastic sheets (such as ABS or PC materials) to form their outer shells. A Plastic Sheet Extruder Machine produces these sheets with uniform thickness and smooth surfaces—two must-haves for subsequent vacuum forming processes that shape the sheets into bag shells. Without these well-made sheets, luggage shells would be prone to cracking, warping, or unevenness, which hurts product durability.

Packaging Industry

The packaging sector—from food to electronics—relies heavily on plastic sheets. For food packaging, the machine creates food-grade plastic sheets that are safe for direct contact with snacks, frozen foods, or ready meals. These sheets also offer moisture resistance to keep food fresh. In electronics packaging, the machine produces anti-static plastic sheets that protect sensitive components like circuit boards from static damage during shipping and storage.

Building and Construction Materials

In construction, plastic sheets are used for decorative and protective purposes. For example, PVC decorative sheets (used for wall panels or furniture veneers) and PP protective sheets (used for covering floors during construction) are made with a Plastic Sheet Extruder Machine. The machine can adjust the sheet's texture, color, and thickness to meet different design needs—like creating wood-grain PVC sheets for interior decor or thick PP sheets for heavy-duty protection.

Daily Necessities Production

Everyday items like plastic storage boxes, toy shells, and kitchen organizers start as plastic sheets. The machine produces sheets that match the specific needs of these products: flexible sheets for lightweight storage boxes, rigid sheets for sturdy toy shells, and heat-resistant sheets for kitchen items. Consistent sheet quality ensures these daily necessities look good, function well, and last through regular use.

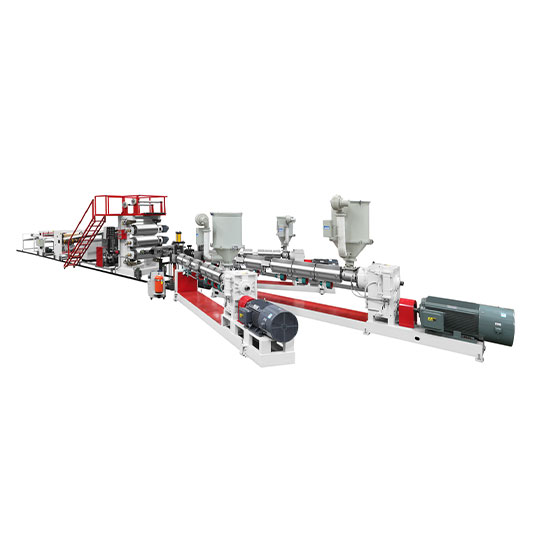

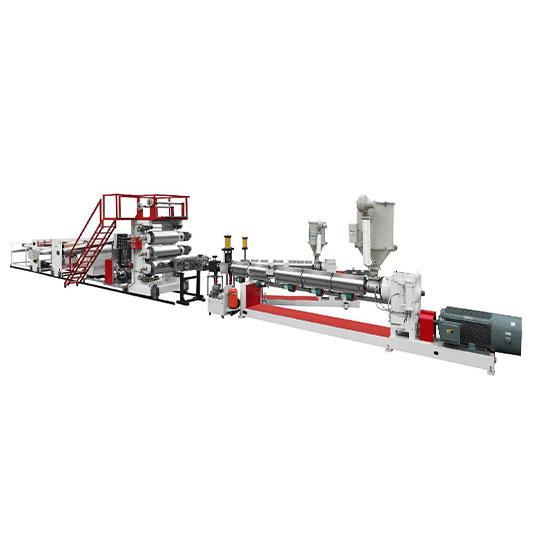

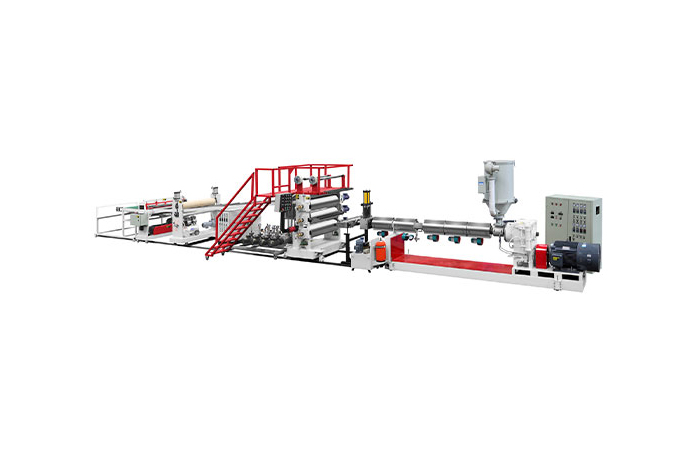

The Machine's Role in Production Lines

A Plastic Sheet Extruder Machine is not a standalone tool—it's the starting point of many production lines. The sheets it makes feed directly into other equipment (like CNC cutters or vacuum forming machines) to turn raw plastic into finished products. This “starting line" role means the machine's reliability directly affects the entire production process: if the sheets are consistent, subsequent steps run smoothly; if not, production slows down or produces defective goods.

Conclusion

From luggage to packaging, construction to daily necessities, the Plastic Sheet Extruder Machine is a backbone of many industries. It turns raw plastic into high-quality sheets that make durable, functional products possible. Understanding these applications helps businesses and buyers recognize how essential this machine is for meeting production goals.

If you want to explore Plastic Sheet Extruder Machines that fit these industry application scenarios and support stable, efficient production, you can visit our product page to learn more about specific models and how they align with different production needs.