Before diving into equipment selection or production planning, many buyers first want to understand the basics of the sheet extrusion process—what it does, how it functions, and which industries rely on it. This article breaks down those key questions with clear, practical explanations, no technical jargon included.

The core steps of how the sheet extrusion process works

The sheet extrusion process is a straightforward method to turn raw plastic materials into flat, continuous sheets of varying thicknesses. It follows a set sequence of steps that ensure consistency and quality:

First, raw plastic (usually in pellet form) is fed into a hopper. The hopper directs the pellets into a heated barrel, where the plastic is melted at controlled temperatures—different plastics (like ABS or PC) need slightly different heat settings to avoid burning or uneven melting.

Next, the melted plastic is pushed through a narrow, flat die by a rotating screw inside the barrel. The die shapes the plastic into a thin, wide sheet as it exits. Right after leaving the die, the sheet moves through a series of cooling rollers. These rollers not only cool the plastic quickly (to lock in its shape) but also smooth its surface and ensure uniform thickness.

Finally, the cooled sheet is pulled through a cutting system that trims it to the desired length or width. The finished sheets are then rolled up for storage or sent to the next stage of production (like vacuum forming for luggage parts).

Key application areas for the sheet extrusion process

The sheet extrusion process is versatile—its output (plastic sheets) is a foundational material for many industries. Here are the most common uses buyers should know:

Packaging industry

Plastic sheets from this process are widely used to make packaging products. For example, thin, flexible sheets are turned into blister packs (for electronics or pharmaceuticals), while thicker sheets become food trays or storage containers. The process allows for food-safe plastic options, making it ideal for this sector.

Daily goods manufacturing

Many everyday items start with plastic sheets from extrusion. Luggage shells, for instance, use ABS or PC sheets (produced via this process) as their base material—these sheets are strong yet lightweight, perfect for travel gear. Other items include plastic tablecloths, shower curtains, and even some toy components.

Construction and building materials

In construction, the sheet extrusion process produces rigid plastic sheets used for wall panels, ceiling tiles, and window casings. These sheets are resistant to moisture and wear, making them a durable alternative to wood or metal in certain areas (like bathrooms or outdoor patios).

Electronics industry

Thin, precise plastic sheets from this process are used to make components for electronics. They can act as insulators inside devices, or as protective covers for screens and control panels—since the process allows for tight thickness control, it meets the strict standards of electronic manufacturing.

Why understanding this process matters for buyers

Knowing the sheet extrusion process helps buyers make smarter decisions. For example, if you’re producing luggage shells, understanding that cooling speed affects sheet strength can help you communicate better with equipment suppliers about your needs. Or if you’re in packaging, knowing which plastics work best in the process can prevent costly mistakes with material selection.

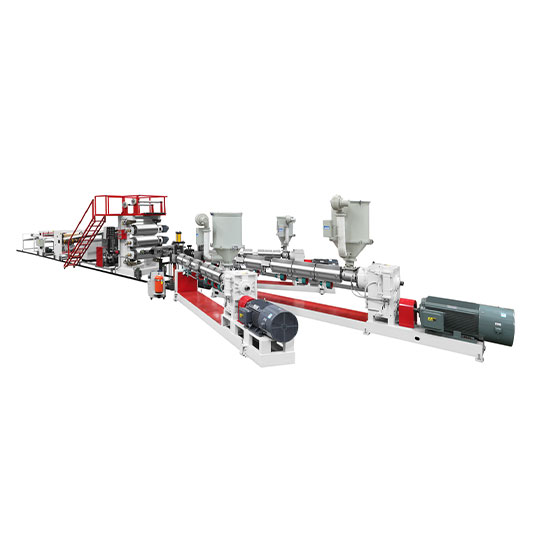

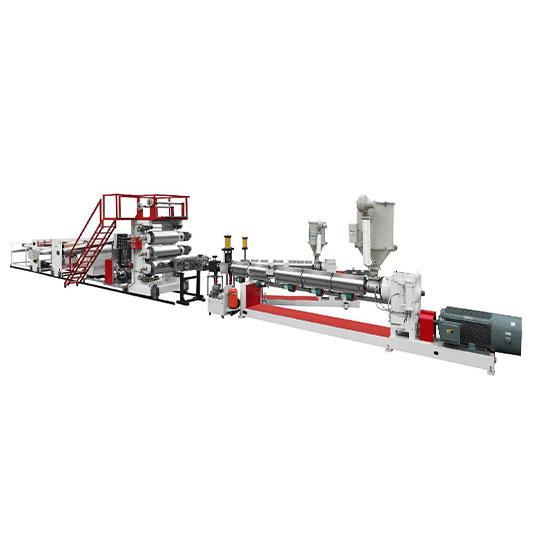

If you’ve learned the basics of the sheet extrusion process and are now looking for equipment that aligns with these steps—whether for producing ABS sheets, PC sheets, or other plastic materials—you can explore our sheet extrusion machines on the Wenzhou Chaoxu Machinery product page. Our equipment is designed to match the core steps of this process, ensuring consistent, high-quality plastic sheets for your industry.