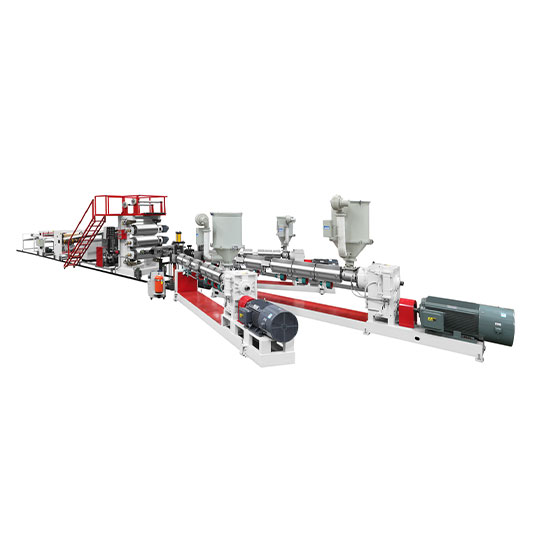

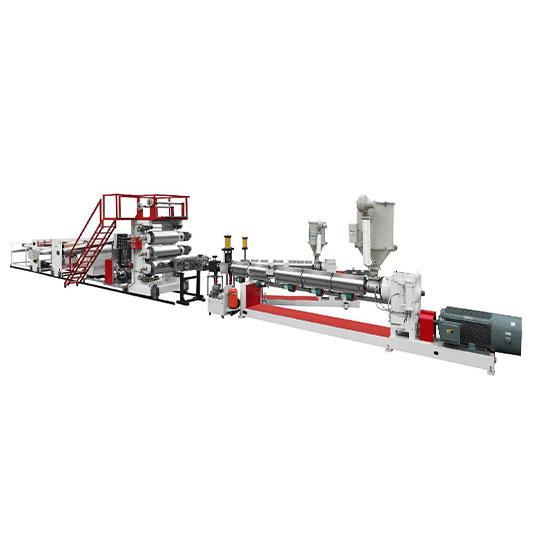

Plastic sheet extruder machines are essential tools for creating flat plastic sheets used in countless industries. But how do you know when investing in one makes sense? Let’s explore the key situations where a plastic sheet extruder machine becomes indispensable.

When Producing Large Volumes of Plastic Sheets

Businesses that depend on consistent, high-volume plastic sheet usage benefit most from a plastic sheet extruder machine. Sectors like packaging—where products need protective or branded plastic layers—often face this need.

Instead of purchasing pre-made sheets in bulk, which ties up storage space and increases long-term costs—such as supplier markup or shipping fees for bulk orders, producing sheets on-site with an extruder lets you manage production schedules flexibly. For example, a company manufacturing food containers might need thousands of uniform plastic sheets weekly. An extruder can run continuously to meet this demand, ensuring a steady supply without relying on external suppliers.

When Working With Diverse Plastic Materials

Different projects require plastic sheets made from various materials—each with unique traits. ABS is tough for heavy-duty uses, PC offers clarity and impact resistance, and PVC excels in outdoor durability. A plastic sheet extruder machine excels here because it can handle multiple materials.

Imagine creating products for both indoor and outdoor applications. With an extruder, you can switch between materials smoothly to craft sheets tailored to each environment—like using UV-resistant PVC for outdoor signs and clear PC for indoor display cases. This quick material changeover and flexibility mean your products meet specific needs without relying on separate suppliers for different pre-made sheets.

When Precision in Sheet Thickness Is Critical

Some applications demand plastic sheets with extremely precise thickness. Medical devices, for instance, use plastic components that must meet strict size standards for safety and performance. A plastic sheet extruder machine allows you to adjust settings to produce sheets with consistent, fine-tuned thickness.

Without this precision, sheets might be overly thick (adding unnecessary weight and cost) or too thin (risking breakage). An extruder gives you the control to create sheets that match exact specifications, ensuring your end products function as intended.

Conclusion

A plastic sheet extruder machine is vital when you need large quantities of sheets, work with multiple plastic materials, or require precise thickness control. It brings efficiency, flexibility, and accuracy to your production process.

If you encounter any of these scenarios and want to learn more about how a plastic sheet extruder machine can support your operations, visit our Plastic Sheet Extruder Machine product page to explore options suited to your needs.