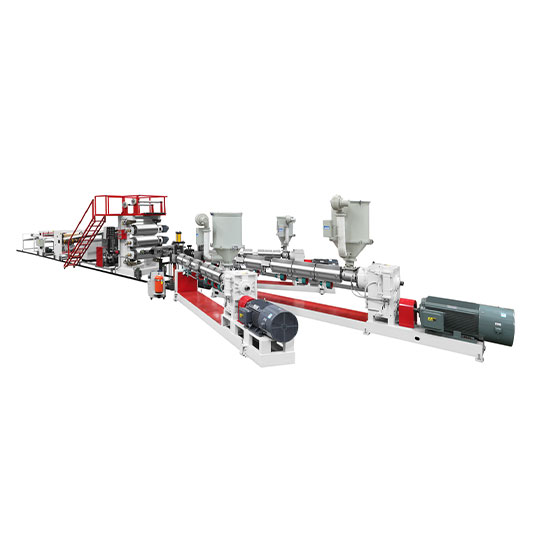

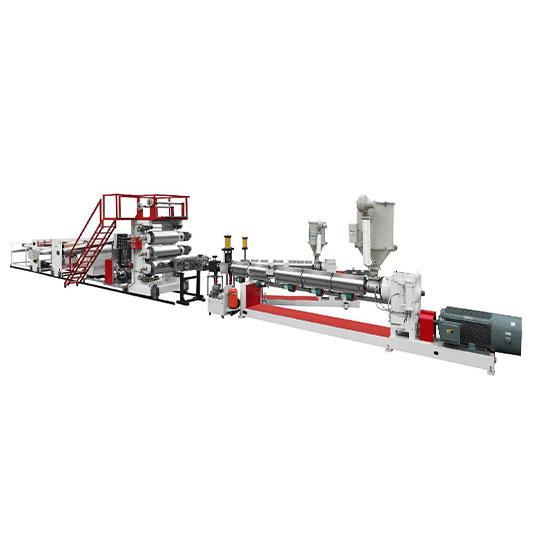

Plastic sheet extruder machine is a device used to plasticize raw materials and extrude them into shapes. It usually consists of several parts such as feeding device, screw, barrel, die and so on.

Working principle of plastic sheet extruder machine:

The working principle of the plastic sheet extruder machine is to melt the plastic particles or powder by heating, and then extrude the molten plastic into flat or special-shaped plastic sheets through the extrusion action of the extruder head die.

Plastic sheet extruder machine mainly includes four parts: feeding device, melting container, forming die and auxiliary equipment.

1. Feeding device: it is mainly responsible for uniformly conveying plastic particles or powder into the melting container. This part contains components such as hopper, conveyor and meter.

2. Melting container: it is mainly responsible for heating and melting plastic particles or powder to transform them into a molten state with strong plasticity. This part is heated by high temperature heat source.

3. Forming die: it is mainly responsible for extruding plastic materials in molten state into plastic sheets with required shapes. The die design of this part is flexible and diverse, which can meet different needs.

4. Auxiliary equipment: it is mainly responsible for cooling and setting the molded plastic sheet, and cutting or winding it.